Water pressure regulation plays a critical role in maintaining your water heater's safety, efficiency, and longevity. Many homeowners underestimate the importance of proper pressure management until they face costly repairs, system failures, or safety hazards caused by excessive water pressure.

High water pressure doesn't just affect your water heater—it impacts your entire plumbing system, appliances, and fixtures throughout your home. Understanding how water pressure affects your water heater and implementing proper pressure regulation can prevent thousands of dollars in damage while ensuring safe, reliable operation for years to come.

This comprehensive guide explores everything you need to know about water pressure regulation, from identifying pressure problems to installing and maintaining pressure relief systems that protect your investment and keep your family safe.

Understanding Water Pressure and Its Impact on Water Heaters

Water pressure measures the force exerted by water against the walls of pipes, fittings, and appliances in your plumbing system. Normal residential water pressure typically ranges between 40-60 PSI (pounds per square inch), with most water heaters designed to operate safely within this range.

When water pressure exceeds recommended levels, it creates stress on water heater components, accelerates wear, and can lead to premature failure. High pressure forces water through seals, gaskets, and connections more aggressively, causing leaks and component damage that might not be immediately apparent.

How Water Pressure Affects Different Water Heater Types

Tank water heaters experience pressure stress differently than tankless systems. Traditional tank units must withstand constant pressure against their walls and internal components, while tankless systems face pressure fluctuations during operation cycles.

Key pressure-related concerns include:

- Tank stress: Excessive pressure can cause tank walls to weaken and eventually fail

- Seal deterioration: High pressure accelerates wear on gaskets and seals

- Valve problems: Pressure relief valves may activate prematurely or fail to operate properly

- Pipe strain: Connected plumbing experiences increased stress and potential failure

Signs of High Water Pressure Problems

Recognizing early warning signs of high water pressure can prevent serious damage to your water heater and plumbing system. Many symptoms develop gradually, making them easy to overlook until significant problems occur.

Physical Indicators

Watch for these physical signs that suggest excessive water pressure:

- Frequent leaks: Recurring leaks at pipe joints, faucets, or appliance connections

- Water hammer: Loud banging sounds when turning water on or off

- Premature fixture wear: Faucets, toilets, and appliances failing sooner than expected

- Pressure relief valve discharge: Water heater relief valve releasing water regularly

- High water bills: Unexplained increases in water consumption

Performance Issues

High water pressure can manifest through various performance problems:

- Inconsistent water temperature from fixtures

- Shorter appliance lifespans throughout your home

- Frequent plumbing repairs and maintenance needs

- Unusual noises from pipes and water heater during operation

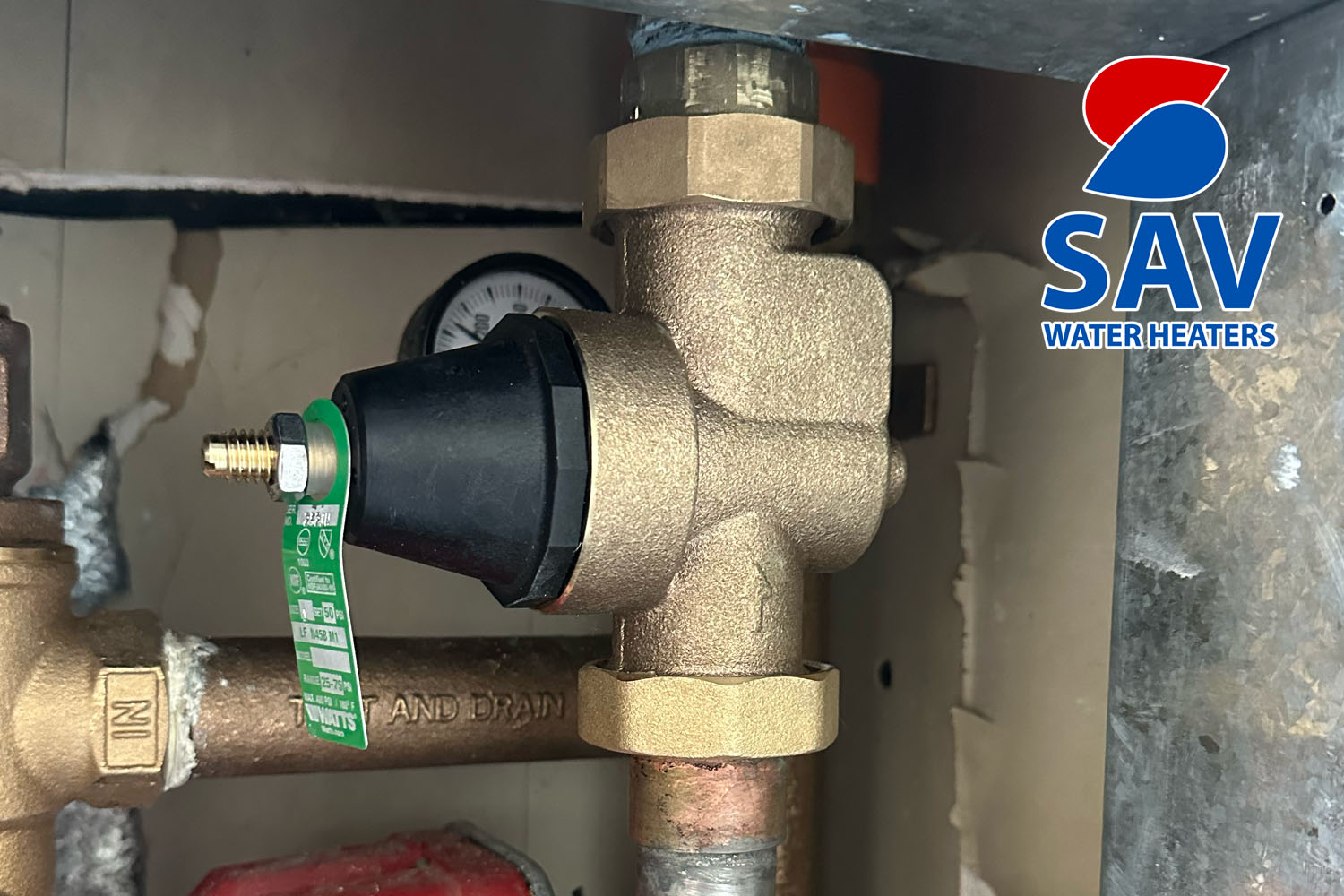

The Role of Pressure Reducing Valves

Pressure reducing valves (PRVs) serve as the first line of defense against high water pressure entering your home. These devices automatically reduce incoming water pressure to safe levels, protecting your entire plumbing system including your water heater.

How Pressure Reducing Valves Work

PRVs use spring-loaded mechanisms to control water flow and maintain consistent downstream pressure regardless of fluctuations in street pressure. When properly installed and adjusted, they ensure your water heater receives water at safe, consistent pressure levels.

Modern pressure reducing valves offer several advantages:

- Adjustable settings: Allow customization for specific pressure requirements

- Built-in gauges: Provide real-time pressure monitoring

- Bypass capabilities: Enable maintenance without shutting off water supply

- Strainer protection: Filter debris that could affect valve operation

Installation Considerations

Proper PRV installation requires professional expertise to ensure optimal performance and code compliance. Installation factors include valve sizing, placement location, and integration with existing plumbing systems.

Critical installation elements:

- Correct valve sizing based on flow requirements

- Proper upstream and downstream pressure measurements

- Adequate clearance for maintenance access

- Integration with water meter and shutoff locations

Thermal Expansion Tanks: Essential Protection

Thermal expansion tanks protect water heaters from pressure spikes caused by thermal expansion—the natural increase in water volume as it heats. Without proper expansion accommodation, heated water creates dangerous pressure buildup that can damage your water heater and plumbing system.

Understanding Thermal Expansion

When water heats from 50°F to 140°F, it expands approximately 2-3% in volume. In closed plumbing systems, this expansion has nowhere to go, creating pressure that can exceed safe operating limits. Thermal expansion tanks provide space for this volume increase, maintaining safe pressure levels.

Thermal expansion becomes problematic when:

- Check valves or pressure reducing valves create closed systems

- Municipal water systems install backflow prevention devices

- Water heaters operate at higher temperature settings

- System pressure already approaches maximum safe levels

Expansion Tank Sizing and Selection

Proper expansion tank sizing depends on water heater capacity, system pressure, and temperature settings. Undersized tanks provide inadequate protection, while oversized tanks may not function properly or cost more than necessary.

Sizing considerations include:

- Water heater tank capacity or flow rate for tankless systems

- Maximum operating temperature settings

- System pressure ranges and PRV settings

- Plumbing system configuration and volume

Temperature and Pressure Relief Valve Maintenance

Temperature and pressure relief (TPR) valves serve as critical safety devices, automatically releasing water when temperature or pressure exceeds safe limits. Understanding what causes water heater leaks often involves TPR valve operation and maintenance requirements.

TPR Valve Operation

TPR valves operate through spring-loaded mechanisms designed to open at specific temperature (usually 210°F) or pressure (typically 150 PSI) thresholds. When activated, they discharge water to relieve dangerous conditions and prevent catastrophic failure.

Proper TPR valve function requires:

- Regular testing to ensure proper operation

- Clear discharge piping to safe drainage locations

- Replacement when showing signs of wear or corrosion

- Professional assessment if frequent activation occurs

Testing and Replacement Schedule

TPR valves should be tested annually to verify proper operation. Testing involves lifting the valve handle to ensure water flows freely and stops completely when released. If the valve fails to operate correctly or continues dripping after testing, immediate replacement is necessary.

Water Pressure Monitoring and Measurement

Regular pressure monitoring helps identify problems before they cause damage. Simple pressure gauges provide ongoing system monitoring, while professional testing offers comprehensive pressure analysis.

DIY Pressure Testing

Homeowners can perform basic pressure testing using standard water pressure gauges available at hardware stores. These gauges attach to hose bibs or laundry connections to provide accurate pressure readings.

Testing procedures include:

- Testing at multiple locations throughout the home

- Measuring pressure at different times of day

- Recording readings before and after appliance usage

- Documenting pressure variations during peak usage periods

Professional Pressure Analysis

Professional pressure analysis provides comprehensive system evaluation, including flow testing, pressure mapping, and component assessment. Professional water heater maintenance often includes pressure system evaluation as part of comprehensive service.

Common Pressure Regulation Problems

Understanding common pressure regulation failures helps homeowners recognize when professional intervention is needed. Most pressure problems develop gradually but can cause sudden, expensive damage when they reach critical points.

Pressure Reducing Valve Failures

PRV failures typically result from wear, debris, or improper adjustment. Failed valves may stick open (allowing high pressure) or closed (restricting flow), both creating problems for water heater operation.

Common PRV problems include:

- Sticking mechanisms: Internal components bind due to mineral deposits

- Worn springs: Reduced tension affects pressure regulation accuracy

- Debris accumulation: Particles interfere with valve operation

- Adjustment drift: Settings change over time due to vibration or wear

Expansion Tank Issues

Thermal expansion tanks can fail through bladder rupture, improper pressure settings, or sizing problems. Failed expansion tanks lose their ability to accommodate thermal expansion, leading to pressure spikes that damage water heaters.

Signs of expansion tank failure:

- Water discharging from TPR valve during heating cycles

- Pressure fluctuations throughout the system

- Tank feels heavy (indicating water in air chamber)

- Visible corrosion or damage to tank exterior

Installation and Replacement Guidelines

Proper installation of pressure regulation components requires professional expertise to ensure safety, code compliance, and optimal performance. While some homeowners attempt DIY installation, professional installation guarantees proper sizing, placement, and configuration.

When to Install Pressure Regulation

New pressure regulation installation becomes necessary when:

- Testing reveals pressure consistently above 80 PSI

- Municipal water pressure changes affect your system

- Installing new water heater with different pressure requirements

- Adding appliances sensitive to pressure fluctuations

- Building codes require pressure regulation for new construction

Replacement Timing

Pressure regulation components typically last 5-10 years depending on water quality and usage. Signs it's time to replace your water heater often coincide with pressure system component replacement needs.

Replacement indicators include:

- Inconsistent pressure regulation performance

- Visible corrosion or physical damage

- Frequent adjustments needed to maintain proper pressure

- Age approaching manufacturer recommendations

Professional vs. DIY Pressure System Work

While homeowners can perform basic pressure monitoring and testing, installation and repair of pressure regulation systems typically require professional expertise due to safety considerations and code requirements.

Professional Services

Professional pressure system services include:

- Comprehensive pressure analysis and system design

- Proper component sizing and selection

- Code-compliant installation and testing

- Integration with existing plumbing systems

- Warranty coverage and ongoing support

Professional water heater repair services often include pressure system evaluation and correction as part of comprehensive system maintenance.

DIY Limitations

Homeowner activities should focus on monitoring and basic maintenance rather than installation or major repairs. Safe DIY activities include pressure testing, visual inspections, and routine cleaning around components.

Cost Considerations and Benefits

Investing in proper pressure regulation provides significant long-term benefits that far exceed initial costs. While pressure regulation systems require upfront investment, they prevent expensive damage and extend equipment lifespans throughout your home.

Installation Costs

Typical pressure regulation installation costs include:

- Pressure reducing valve: $300-800 including installation

- Thermal expansion tank: $200-500 including installation

- System pressure analysis: $150-300 for professional assessment

- Complete system upgrade: $500-1,500 depending on complexity

Long-term Savings

Proper pressure regulation prevents costly damage including:

- Premature water heater replacement ($1,500-4,000+)

- Plumbing repairs from pressure damage ($500-2,000+)

- Appliance replacement from pressure stress ($1,000-5,000+)

- Water damage from leaks and failures ($2,000-10,000+)

Preventive Maintenance Best Practices

Regular maintenance of pressure regulation systems ensures optimal performance and extends component lifespans. Water heater maintenance tips should include pressure system components for comprehensive system care.

Annual Maintenance Tasks

Essential annual maintenance includes:

- Pressure testing at multiple system locations

- TPR valve operation testing

- Visual inspection of all pressure components

- Expansion tank pressure verification

- PRV adjustment verification and cleaning

Professional Inspection Schedule

Professional pressure system inspection should occur every 2-3 years or when problems are suspected. Professional technicians can identify potential issues before they cause damage and ensure all components operate within safe parameters.

Emergency Pressure Situations

Understanding how to respond to pressure emergencies protects your home and family from dangerous situations. High pressure emergencies require immediate action to prevent catastrophic damage or safety hazards.

Emergency Response Steps

When facing high pressure emergencies:

- Shut off main water supply to stop pressure buildup

- Turn off water heater to prevent further heating and expansion

- Relieve pressure by opening hot water faucets

- Check TPR valve for proper discharge operation

- Contact professional service for immediate assessment

Warning Signs Requiring Immediate Action

Contact emergency services immediately if you notice:

- Continuous TPR valve discharge

- Water heater tank bulging or deformation

- Multiple simultaneous leaks throughout the system

- Unusual noises suggesting system stress

- Water pressure exceeding 100 PSI

Frequently Asked Questions

What is the ideal water pressure for a water heater?

Most water heaters operate optimally between 50-60 PSI. Pressure below 40 PSI may result in poor performance, while pressure above 80 PSI can cause premature wear and potential safety issues. Installing a pressure reducing valve helps maintain pressure within this ideal range.

How often should I test my water pressure?

Test water pressure at least twice per year, and any time you notice changes in system performance. Use a simple pressure gauge attached to a hose bib or laundry connection to get accurate readings. Test at different times of day to identify pressure variations.

Do I need a thermal expansion tank with my water heater?

Thermal expansion tanks are required in closed plumbing systems, which include most homes with pressure reducing valves, check valves, or backflow prevention devices. Even if not required by code, expansion tanks provide valuable protection against pressure spikes caused by thermal expansion.

How long do pressure reducing valves last?

Quality pressure reducing valves typically last 5-10 years with proper maintenance. Factors affecting lifespan include water quality, pressure fluctuations, and usage patterns. Regular testing and maintenance can extend valve life and ensure optimal performance.

Can high water pressure damage my tankless water heater?

Yes, high water pressure can damage tankless water heaters by stressing internal components, affecting heat exchanger performance, and causing premature wear on seals and gaskets. Tankless systems are particularly sensitive to pressure fluctuations during operation cycles. Learn more about tankless water heater installation requirements including proper pressure regulation.

What causes my TPR valve to discharge water frequently?

Frequent TPR valve discharge usually indicates excessive pressure or temperature in your water heater. Common causes include failed thermal expansion tanks, high inlet water pressure, thermostat malfunctions, or undersized pressure relief systems. Professional diagnosis is recommended for recurring discharge issues.

Should I install a pressure regulator myself?

Pressure regulator installation typically requires professional expertise due to safety considerations, code requirements, and the need for proper sizing and configuration. Improper installation can create safety hazards and void warranties. Professional installation ensures optimal performance and code compliance. For comprehensive system solutions, consider professional water heater replacement services that include pressure system evaluation.

How do I know if my expansion tank has failed?

Signs of expansion tank failure include frequent TPR valve discharge, the tank feeling heavy when tapped, water pressure fluctuations, and visible corrosion or damage. A simple test involves pressing the air valve—if water comes out instead of air, the tank's internal bladder has failed and requires replacement.